My 1952 Corbitt model D808T29 tractor was originally purchased from the Corbitt factory in Henderson, North Carolina by Mr. Thomas K. Beitelman, who was a Corbitt operator and Corbitt dealer in Allentown, Pennsylvania.

Mr. Beitelman owned four Corbitts, including my 1952 wide-cab model D808T29 and my 1949 28TD. The other two were narrow-cab D808T29’s. One was destroyed in a wreck and the other was purchased by one of the folks in North Carolina who raced Corbitts on oval tracks.

When I received my D808T29, it still ran good, but the chassis was worn out. There was a lot of lost motion in the front axle king-pins and spring eye pins and bushings. It really started to shimmy at about 60 MPH. There were also engine coolant leaks, the worst of which was from the fit of the heads to the engine block. And there were longitudinal cracks in the top and bottom flange bends of the frame rails, just above the rear drive axle. They were most likely caused by insufficient air pressure in the tag axle air springs. Air pressure is adjustable to allow more weight to be placed on the drive axle during slick road conditions. I imagine that was the case during much of this truck’s career as it was operated in Pennsylvania, New York, Ohio and other northern states.

Mr. Beitelman added the Neway tag axle in the early 1960’s, when weight laws were changed in the east so that operators could haul more weight by adding additional axles. The original saddle-type fuel tank was also replaced with higher capacity round tanks and a Bostrom Viking-T-Bar seat was added for driver comfort. The original fixed fifth wheel was replaced with an ASF Air-O-Slide model. I decided to keep these modifications as they were present for about half the life of the truck. The last year my D808T29 was in operation was 1979.

I stripped my D808T29 to the frame and sandblasted everything. I then spliced in new frame rails at the rear of the cab to replace the cracked rails and began the process of repair and reassembly on the rest of the truck. The replacement frame rails were from an original Corbitt chassis. The round fuel tanks were bent and in bad shape so I decided to replace them with 80 gallon Peterbilt tanks. I also changed the two-speed rear axle gears to ones with faster ratios. Those gears were a factory option when the truck was new. The top speed is now a little over 80 MPH.

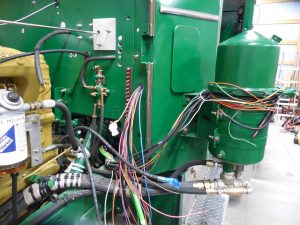

I also went through all other components including the engine. The wet sleeve cylinder liners were replaced because they had heavy cavitation erosion, as is common with Cummins diesels. I also added a pre-lube pump to the engine and a coolant filter to help prevent cavitation erosion. I also use Rotella coolant, which is formulated to prevent those types of problems. A modern Racor fuel filter was also added for a cleaner fuel supply. The original engine was a Cummins model HRBB-600 with 175 horsepower. That engine was ruined while in service for Mr. Beitelman. So he replaced it with a model NHB-600 from a Mack. He also upgraded that engine to 220 horsepower with a PT fuel system and added an external oil cooler, as NHB-600’s did not have oil coolers. A larger radiator from a newer truck was also installed at that time as was a large dry-type air cleaner and by-pass oil filter.

I replaced the front axle kingpins, spring eye pins and bushings, and steering rod connections, so no more wild shimmy. I also converted the electrical system to negative ground. Seat belts were installed for safety and a pyrometer was added to monitor engine exhaust temperatures. Spring brakes were added on the drive axle for parking and emergencies. I also fabricated a brace for the engine exhaust stack so it would not have to be attached to the cab. And I mounted a large aluminum tool box behind the cab. The air horns are “Super Freighters” that were originally used in the west. Their bells and diaphragms are larger than the ones used on Grovers. All wiring was replaced with plastic coated wire and the original circuit breakers were replaced with fuses. I replaced the original push-pull electrical switches with toggle switches and added knife switches to the battery connections.

The restoration of my D808T29 took many years and a lot of work, but just hearing that old Cummins come back to life again made it all worthwhile.